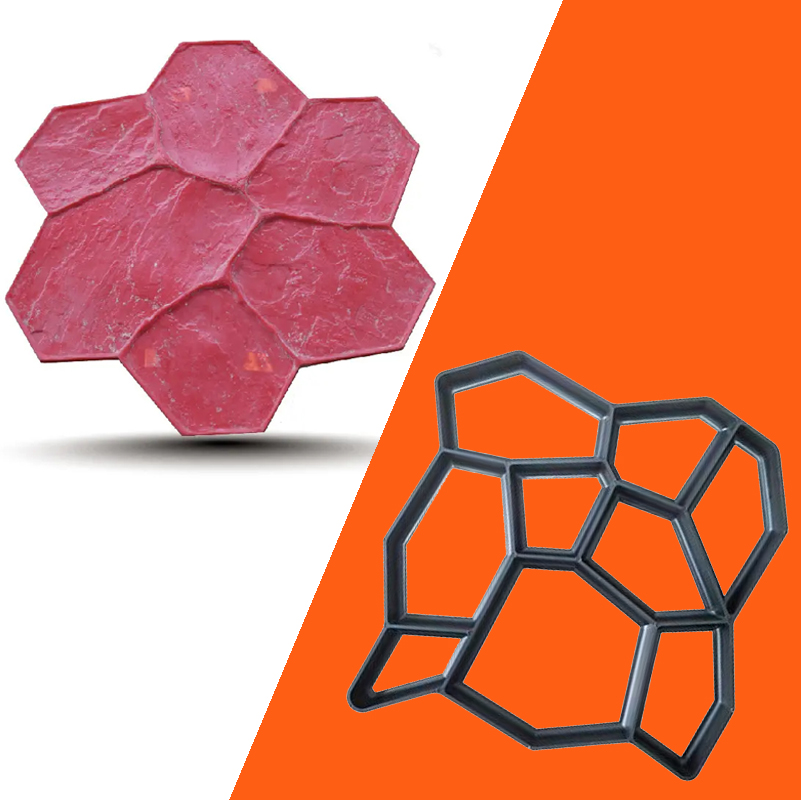

StreetPrint® Color Stamped Pavement

.Solvent-free, high brightness, high penetration, high water resistance, sustainable reaction

.Ready to use after opening the barrel, easy to construct

.Improve the chemical resistance and wear resistance of concrete

.Reduce the water loss of newly poured concrete during the curing process

.Reduce dust on concrete floors

.Environmentally friendly and does not pollute the environment

01

Anti-slip and wear-resistant

The polymer wear-resistant aggregate and silicone modified resin undergo

a cross-linking reaction, which is super wear-resistant and anti-slip.

02

Inorganic bonding

Through nano-silicon polymer infiltration primer treatment, it maintains inorganic bonding with the substrate performance and improves inter layer bonding.

03

Long-lasting color

Polymer mixed aggregate uses inorganic coloring technology, and the topcoat agent provides secondary coloring protection, making it long-lasting and bright.

04

Green and environmentally friendly

Green and environmentally friendly, water-based main emulsion film-forming, low VOC, low organic matter emission into the atmosphere.

05

Good durability

Excellent anti-fouling and anti-pressure performance, good heat resistance, weather resistance and UV aging resistance.

06

Lightweight construction

No need for large equipment, flexible construction, higher efficiency and lower cost.

01 Base surface treatment

Check to ensure that the base surface is clean and dry (construction is not recommended within 48 hours after rainfall), and the moisture content of the base surface is not more than 7% during construction

Check to ensure that the base surface is clean and dry (construction is not recommended within 48 hours after rainfall), and the moisture content of the base surface is not more than 7% during construction

02 Primer construction

After opening the cover, stir evenly, use a roller or spray paint to evenly apply the road surface to ensure that there is no omission on the road surface, the dosage is 0.15-0.2kg/㎡

After opening the cover, stir evenly, use a roller or spray paint to evenly apply the road surface to ensure that there is no omission on the road surface, the dosage is 0.15-0.2kg/㎡

03 Leveling layer construction

Start to paste masking paper, mix materials and scrape the leveling layer mortar

Start to paste masking paper, mix materials and scrape the leveling layer mortar

02

LED lights

2018-07-16

Tilapi, commonly known as: African crucian carp, non...

view

detail

04 Finishing layer construction

Within 10-15min after scraping, spray with a high-pressure sprayer of real stone paint, the thickness is about 1-2mm, the dosage is 1kg-1.5kg/㎡

Within 10-15min after scraping, spray with a high-pressure sprayer of real stone paint, the thickness is about 1-2mm, the dosage is 1kg-1.5kg/㎡